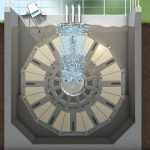

Covolan Têxtil® ® invested on the most modern effluent treatment with MBR (Membrane Bio Reactor) that filtrates water, a nanotechnology. The MBRflat membranes are ultra-filtration system and submerged on biological reactor.

The treated effluent has a high quality and attends to the most rigid standards and, at the same time, attends to future requirement of legislation for effluent´s treatment, diminishing the costs of investing and operation.

Micro and ultrafiltration membranes with the pore 38mm size (compared to a hair thread) separates the clean water to activated sludge. The biomass and practically all the germs and bacteria are withheld on a confident way by membrane as a physical barrier.

The membrane filtration principle is based on the separation of suspended solids on a water solution through a pressure difference. While the water permeates through the membrane, the solids, bacteria and even the most of virus are withheld on concentrated side of membrane surface, where are removed by relative movement.

HUBER technology HUBER uses a high-performance hydrophilic membrane system, with very good filtering properties, with low affinity with the fouling and coating material contained in the wastewater. This allows for high flow rates (up to 60 l / m² h) at low transmembrane pressure (<100 mbar), keeping all solids, bacteria and most germs. In addition to the liquid phase, only low molecule ions and dissolved substances pass through the membrane. Typical surface flow: up to 35 l / m²h.

The necessary transfers for a constant operation of ultrafiltration membranes are achieved through the air flux highly efficient on concentrated side, with just sixth or eighth of membrane surface installed being washed one each time. Beyond that, the intermittent cleaning with low incomes minimizes the energy costs.

This combination eliminates the need of secondary conventional elucidation on a decantation tank. The combined process is called “membrane bioreactor” (MBR).

Ecological Valeu: The permeate produced is hygienically safe, odorless and free of particles and, also allows the direct reusing of effluent free of bacteria and germs like service water (by irrigation, as an example) and low cost.

Membrane Bioreactors (MBR) come from the most new and advanced technology for municipal and industrial residuals water treatment.

The clarification process in our industrial plant increases the performance on our effluent’s treatment station.

Curiosities: The Schulungsinstitut für Membrantechnik Seelscheid e.V(SIMAS), a training center of membrane technology in Germany. SIMAS is financed by German state of North Rhine-Westphalia. The SIMAS objectives is to teach technology theory of membranes and training its practice operation.

Sustainability is the capacity of keeping the ecosystem balance.

** "transmembranar: A transmembrane protein is a type of membrane protein that embraces the entire biological membrane to which it is permanently attached - that is, it covers that membrane from side to side and can cover the lipid bilayer once or several times. "**

Covolan Têxtil®

The treated effluent has a high quality and attends to the most rigid standards and, at the same time, attends to future requirement of legislation for effluent´s treatment, diminishing the costs of investing and operation.

Micro and ultrafiltration membranes with the pore 38mm size (compared to a hair thread) separates the clean water to activated sludge. The biomass and practically all the germs and bacteria are withheld on a confident way by membrane as a physical barrier.

The membrane filtration principle is based on the separation of suspended solids on a water solution through a pressure difference. While the water permeates through the membrane, the solids, bacteria and even the most of virus are withheld on concentrated side of membrane surface, where are removed by relative movement.

HUBER technology HUBER uses a high-performance hydrophilic membrane system, with very good filtering properties, with low affinity with the fouling and coating material contained in the wastewater. This allows for high flow rates (up to 60 l / m² h) at low transmembrane pressure (<100 mbar), keeping all solids, bacteria and most germs. In addition to the liquid phase, only low molecule ions and dissolved substances pass through the membrane. Typical surface flow: up to 35 l / m²h.

The necessary transfers for a constant operation of ultrafiltration membranes are achieved through the air flux highly efficient on concentrated side, with just sixth or eighth of membrane surface installed being washed one each time. Beyond that, the intermittent cleaning with low incomes minimizes the energy costs.

This combination eliminates the need of secondary conventional elucidation on a decantation tank. The combined process is called “membrane bioreactor” (MBR).

Ecological Valeu: The permeate produced is hygienically safe, odorless and free of particles and, also allows the direct reusing of effluent free of bacteria and germs like service water (by irrigation, as an example) and low cost.

Membrane Bioreactors (MBR) come from the most new and advanced technology for municipal and industrial residuals water treatment.

The clarification process in our industrial plant increases the performance on our effluent’s treatment station.

Curiosities: The Schulungsinstitut für Membrantechnik Seelscheid e.V(SIMAS), a training center of membrane technology in Germany. SIMAS is financed by German state of North Rhine-Westphalia. The SIMAS objectives is to teach technology theory of membranes and training its practice operation.

Sustainability is the capacity of keeping the ecosystem balance.

** "transmembranar: A transmembrane protein is a type of membrane protein that embraces the entire biological membrane to which it is permanently attached - that is, it covers that membrane from side to side and can cover the lipid bilayer once or several times. "**

Covolan Têxtil®